Franki piles, or pressure-injected footings (PIFS), are high-capacity, cast-in-place elements constructed using a drop weight and casing.

Common uses

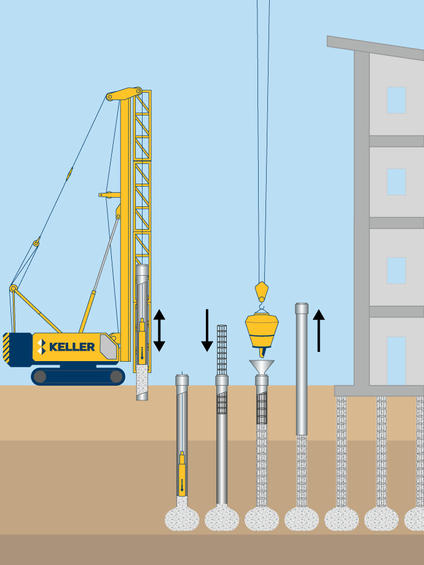

Process

A two to three-foot diameter steel casing is vertically positioned at a planned location. The bottom three to five feet of the casing is filled with a very dry concrete mix and a steel cylinder with a diameter slightly smaller than the casing, then repeatedly dropped inside. The mix locks into the bottom of the casing, and the repeated blows of the drop weight advance the casing to the design depth.

The casing is stopped from advancing further, and additional weight drops eject the dry mix out of the bottom of the casing. The additional dry mix is added and driven from the casing until a design resistance to further displacement is achieved. Reinforcing steel and concrete are then placed in the casing, and the casing is removed.