Slurry walls create barriers to groundwater inflow or subsurface contaminants.

Common uses

Process

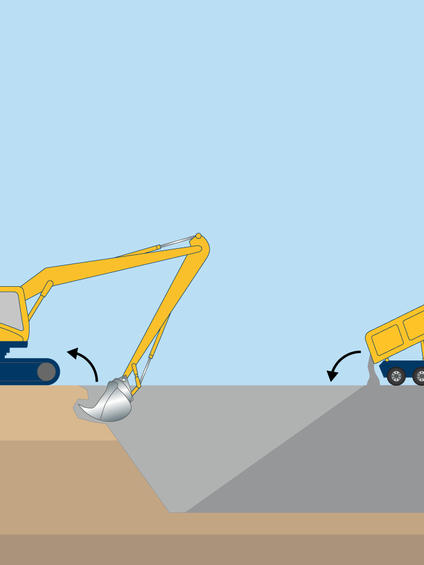

For traditional barrier walls, the trench is excavated through bentonite slurry or cement-bentonite slurry to prevent collapse during excavation. For cement-bentonite slurry walls, the cement-bentonite hardens in the trench to form the wall. When bentonite slurry is used alone, the excavated soil is typically mixed with bentonite and then placed back into the trench to form a soil-bentonite wall. The finished wall creates a groundwater barrier with low permeability.

For structural diaphragm slurry walls, a clam-shell bucket is typically used to excavate individual panels to create the wall and design depth. During excavation, bentonite slurry is added to prevent caving. When design depth is reached, the slurry is displaced with concrete pumped through a tremie pipe to the bottom of the panel, and steel reinforcement is inserted. The finished walls can function as groundwater cutoff and soil retention systems during the excavation phase of the project and then as permanent underground walls with load-carrying capabilities for the finished structure.

Non-traditional methods of slurry cutoff wall construction include the vibrating beam method. A vibratory hammer drives special steel beams to design depth along the wall alignment. The cement-bentonite slurry is injected during the penetration and removal of the beam. The penetrations are overlapped to construct a continuous barrier. The finished wall creates a thin groundwater barrier with low permeability.

Specialist contact

Dale Evans | Senior Business Development Manager | 281-664-1110

Advantages

Quality assurance

Keller has decades of experience installing slurry walls across the globe. A specially developed mix combined with strict quality control ensures consistency and a product installed and designed to withstand the test of time. Samples from the top and bottom of the trench are taken daily, and a series of testing can be done, including slump, specific gravity, bleed, shear strength, and pH.